EN

9 Ton Empty Container Handler

Home - Products - Port Machinery - Empty Container Handler - 9 Ton Empty Container Handler

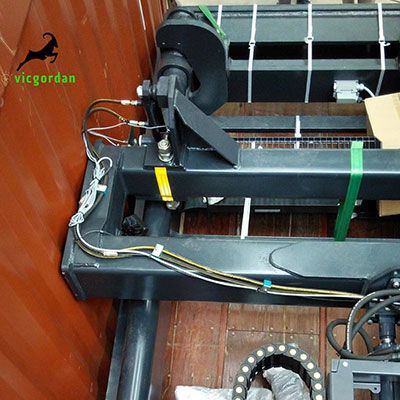

9 tons 9t empty container handler side loader ECH Brand vicgordan vs Fantuzzi, Kalmar, Hyster, Sany, Konecranes, CVS

As we all know, the ECH's walking part is mainly composed of driving wheel, supporting chain wheel, supporting wheel and rail link. Each operation is indispensable to the operation, so when the operation of a certain period of time, these components will appear in varying degrees of wear and tear. The iron armor foam is here to share a few daily maintenance methods, which can reduce the wear of the ECH, and avoid a lot of time and energy to repair it in the future.

Iron armor for you to dispel doubts and reduce wear of ECH tracks

A method of reducing wear in the walking part of a ECH

The first point: if it is found that the wheel can not operate due to failure, it should be repaired immediately.

If a partial sprocket or a support wheel does not continue to operate, it may cause the roller to wear off and even lead to the wear of the rail link. Therefore, in the case of such roller can not run, it is necessary to immediately repair, so as to avoid other failures in time.

Second point: avoid ECH’s moving along the sloping ground or turning suddenly as far as possible.

Long time repeatedly walking and turning on the sloping ground will lead to the side of the rail link with the side of the driving wheel and the steering wheel, which leads to the increase of the degree of wear. Therefore, in the course of operation, it is possible to choose straight line and big turn as far as possible, which can effectively prevent excessive wear.

Third point: regular inspection, reinforcement bolts and nuts can effectively reduce track wear.

Load wheel, caterpillar bolt, drive wheel mounting bolt, running pipe bolt and so on, because the equipment works for a long time easily because of vibration and loosening. If the trackboard bolts are loosened and the equipment continues to operate, the gap between the bolts and the trackboard may occur, resulting in cracks in the trackboard. The gap can also increase the bolt hole between the track and the rail link, which leads to no means of fastening, resulting in the replacement of the track and the track chain.

Although the wear and tear of ECH track is caused by some small details, but it is these small details, if not paid attention to may lead to major failures and consequences. I hope you can share the experience with each other, learn and improve the maintenance operation skills, cherish and protect our revolutionary brothers.

Our range of empty container handlers delivers market-leading strength and stability to ensure precise yet straightforward positioning of containers. The flexible design includes side spreaders for twist-lock (single stacking) or hook (double stacking) handling. Every single element – the lifting mast (also known as the boom), chassis and side spreader – is designed for maximum strength and stability. We provide four basic capacities of 8 or 9 tons for a total stacking height of up to 7+1 containers.

Our empty container handler offering includes solutions for both single and double stacking at different lifting heights, with twist-lock and hook attachment options for load handling. The twist-hook attachment enables easy and fast load leveling for single stacking, while the hook attachment allows double stacking for increased efficiency.

Every container yard must bring down the cost per box moved to stay competitive in this growing, fast paced industry.

vicgordan empty container handlers are designed to perform and last, even while handling heavy or offset double container loads.

THE RIGHT SPREADER FOR YOUR OPERATION

Choosing the right spreader is key to cost effective container handling. And if you don’t double pick yet, you could even discover a new, more efficient container handling approach utilising the right spreader for your operation.

A comprehensive selection of single and double handling spreaders is available to suit your specific needs featuring vertical twistlocks, hook & side clamps and horizontal twistlocks. With a variety of different container sensing systems available, nothing stops you from efficient handling all of the most common types of containers, one or two at a time.

FOR THE OPERATOR

A comfortable operator is more productive. The operator finds their best position with seat and steering column adjustment, and can easily check and adjust truck parameters with the digital display. The operator cabin, open mast design, and smart placement of components provide 360-degree visibility.

The innovative spreader design enables the operator to see the twistlocks or hooks in every load position. And includes ‘reefer correction’ sideshift to easily reposition offset loads. CANbus control and digital operator display with twist lock indication, make it easy and efficient for the operator to lock the load.

FUEL SAVINGS & LOW NOISE LEVELS

A well-tuned and fuel efficient powertrain lowers your fuel consumption. Smart features such as on-demand hydraulics, on-demand cooling and selectable performance modes also contribute to fuel savings, extended component life and reduced noise levels.

DURABILITY AS STANDARD

vicgordan container handlers are designed and built to perform and last in the toughest container yards, offering effortless handling, every day. The robust and heavy-duty core of the machine is capable of lifting two 40ft reefers at once, even with both cooling units on the same side.

The high strength mast accommodates heavier weights and can handle net loads of up to 9 tonnes. For optimal performance and durability, the variable lap mast features a heavy duty 2 over 1 chain system. This new design enhances structural strength and significantly improves chain life, contributing to lower costs and reducing downtime.

EASY SERVICE FOR MORE UPTIME

Not only will you move more in less time, with vicgordan empty container handlers you’ll also notice longer service life of components, and less downtime due to unplanned repair needs.

Reliable, quality components

Daily checks and servicing are completed with ease

Minimum 500hr+ service interval (extended 10.000 hr service interval for the hydraulic oil using regular oil sampling)

Tilting cab for easy access to components

| PERFORMANCE | ||

| Model | VG-ECH90-7 | |

| Power unit | Diesel | |

| Operation type | Driver seated | |

| Load capacity | (kg) | 9000 |

| Max. stacking layer | 6 | |

| Lift speed, laden/unladen | m/s | 0.55/0.60 |

| Lowering speed, laden/unladen | m/s | 0.60/0.60 |

| Travel speed, laden/unladen | Km/h | 26/28 |

| Climbing ability, laden | % | 38 |

| Tractive force | kN | 157.5 |

| DIMENSIONS | ||

| Wheelbase | y (mm) | 4520 |

| Height of mast, lowered | h1 (mm) | 11111 |

| Tilt angle, forward/backward | α/β(/°) | 3/4 |

| Height of mast, extended | h4 (mm) | 19244 |

| Height of cabin | h6 (mm) | 4326 |

| Height, operator's seat | h7 (mm) | 3226 |

| Twist lock height, lowered | h13 (mm) | 2290 |

| Max. twistlock height | h3 (mm) | 18642 |

| Overall length | l1 (mm) | 6850 |

| Length to spreader face | l2 (mm) | 6682 |

| Overall width | b1/b2 (mm) | 4120/2570 |

| Width of spreader 20'/40' | b3 (mm) | 6050/12150 |

| Turning radius | Wa (mm) | 6300 |

| Wheelspan, front wheels | b10 (mm) | 3280 |

| Wheelspan, rear wheel | b11 (mm) | 2171 |

| WEIGHT | ||

| Service weight | kg | 32280 |

| Axle load with load, front/rear | kg | 36610/10670 |

| Axle load without load, front/rear | kg | 22480/15800 |

| ENGINE | ||

| Brand | Cummins | |

| Type | QSM6.7 | |

| Cylinder no./displacement | 6/6700 cm3 | |

| Rated power @ rated speed | 164kw @ 2200rpm | |

| Max. torque | 949Nm@ 1500rpm | |

| Rated current of alternator | 100A | |

| Battery | 24V (2x12/110) | |

| TRANSMISSION | ||

| Brand | ZF/3WG211 AUTO | |

| Transmission | Auto-shift/interlock | |

| Clutch type | Torque converter | |

| Gear no. | 3F/3R | |

| BRAKE SYSTEM | ||

| Service brake | wet-disc | |

| Parking brake | Brake enabled when power off | |

| DRIVE AXLE | ||

| Brand | Kessler/Germany | |

| Model | D81PL488-NLB | |

| STEERING AXLE | ||

| Model | OMCI | |

| Steering type-single cylinder | Double action cylinder | |

| TYRES | ||

| Drive wheels | 14.00-24 28PR | |

| Steering wheels | 14.00-24 28PR | |

| Type | Pneumatic | |

| Pressure | 10 bar | |

| Quantity, front/rear | 4/2 | |