EN

60 ton mining fork

Home - Products - Attachments - Forks - 60 ton mining fork

BeiJing Vicgordan Industrial Co., Ltd is a professional manufacturer of large forklifts, forks and accessories in China. The factory is located in Aishan Industrial Park, Gangcheng District, Jinan City, covering an area of 50,000 square meters, with a plant area of more than 15,000 square meters and an office area of more than 2,000 square meters. The company has many years of experience in fork production, has advanced production technology, technical equipment and testing equipment, integrates production, marketing and research into one, and has two utility model patents and three software copyright patents. Have a free forging and two profile fork production line, the fork's rated load is 0.5t to 80t. With an annual output of 300,000 forks, 12,000 tons of production capacity.

At present, the main types of production and sales include standard forks, large-tonnage sleeve-type forks, integral port machinery forks, sliding port machinery forks, mining forks, forks for forklifts, agricultural forks, There are a total of more than 15 types and more than 300 specifications, such as through-rod forks, stone patent forks, screw-pitch forks, hydraulic forks, folding forks and fork extensions. Forklift attachments mainly include side shifters, flippers, forklift backs, pinch forks, cargo fork sleeves, etc. The main equipment includes: 1t, 3t electro-hydraulic hammer (with operating machine), 800t, 500t three-way hydraulic machine, calibration machine, shot blasting machine, flame cutting machine, wire cutting machine and equipped with complete auxiliary facilities.

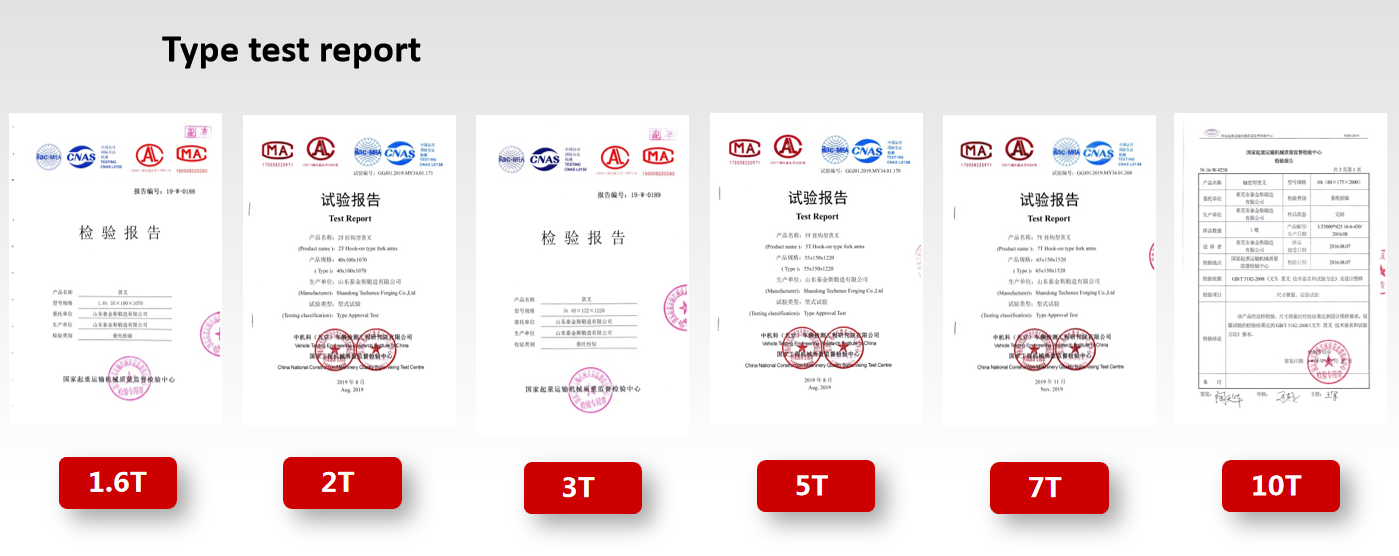

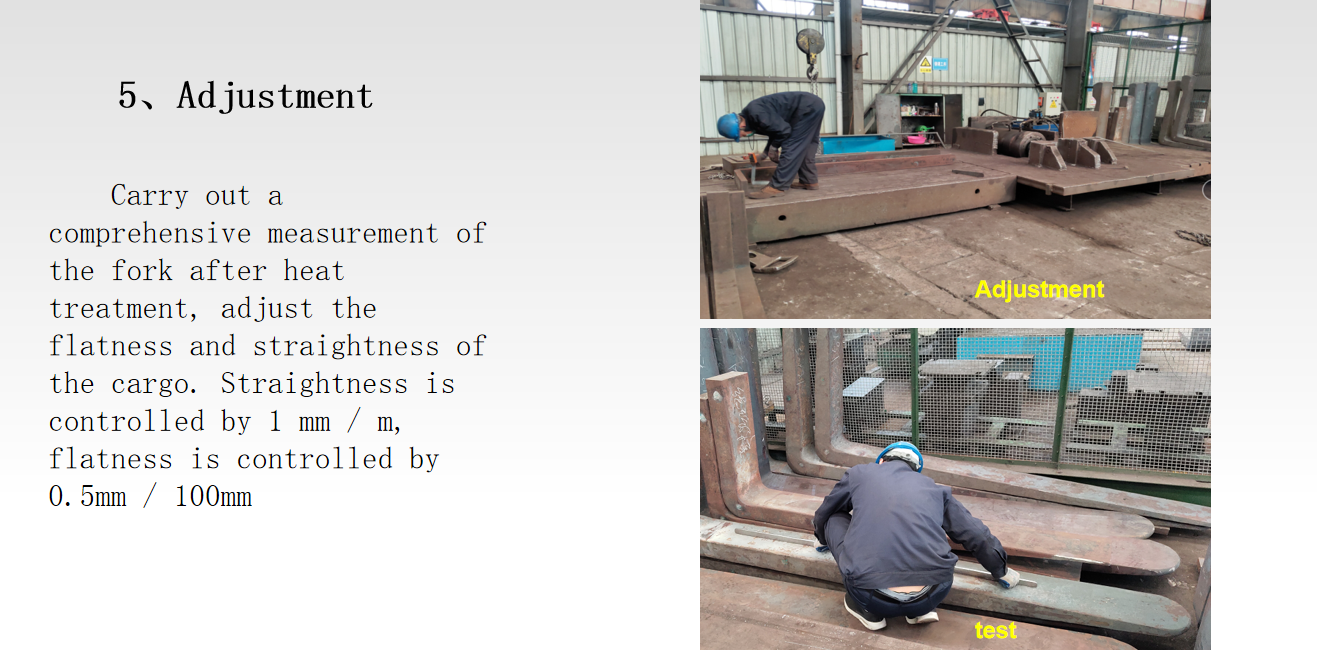

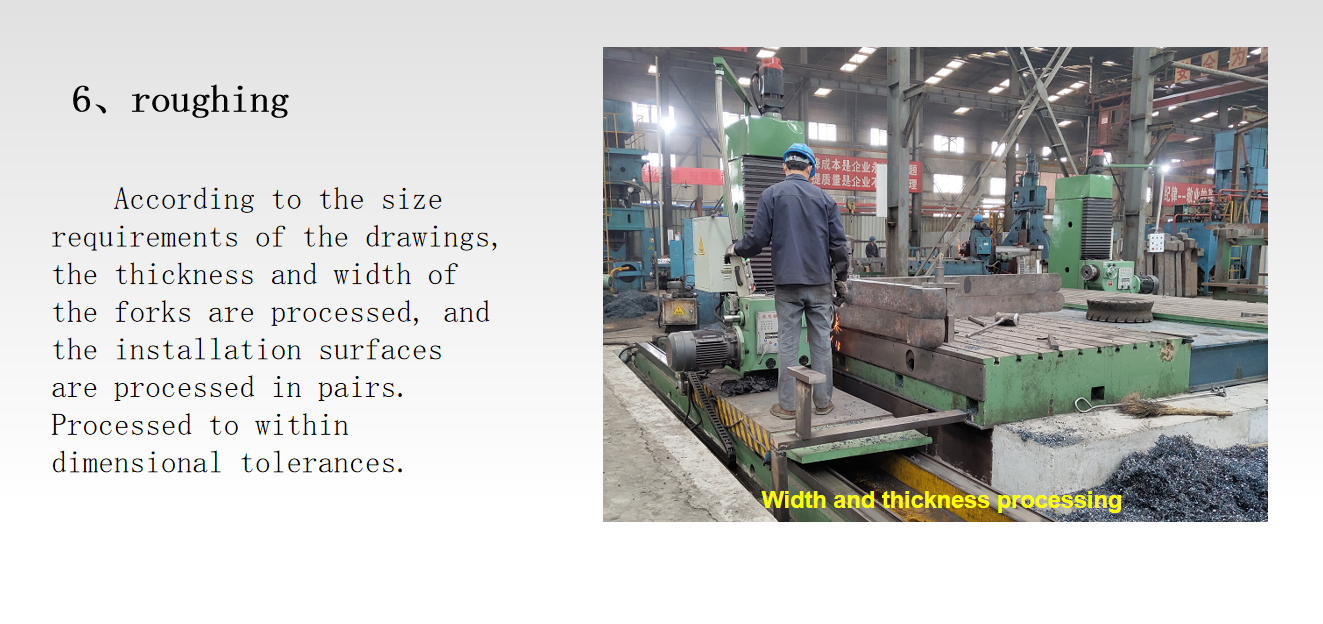

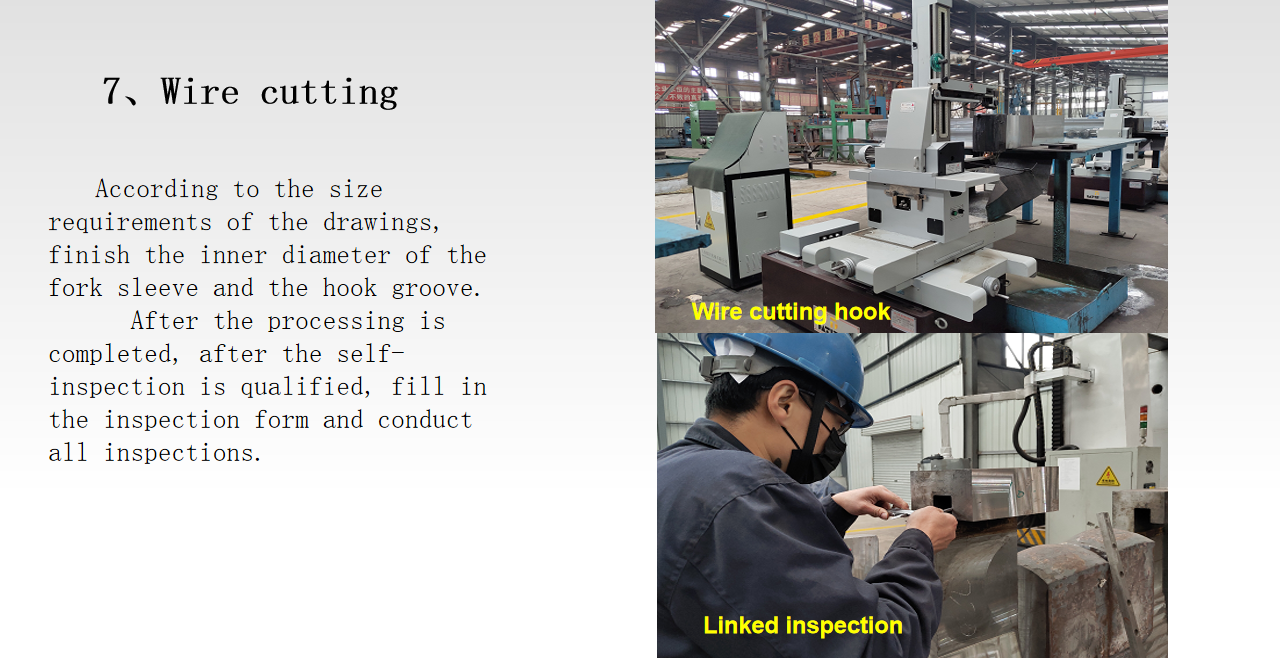

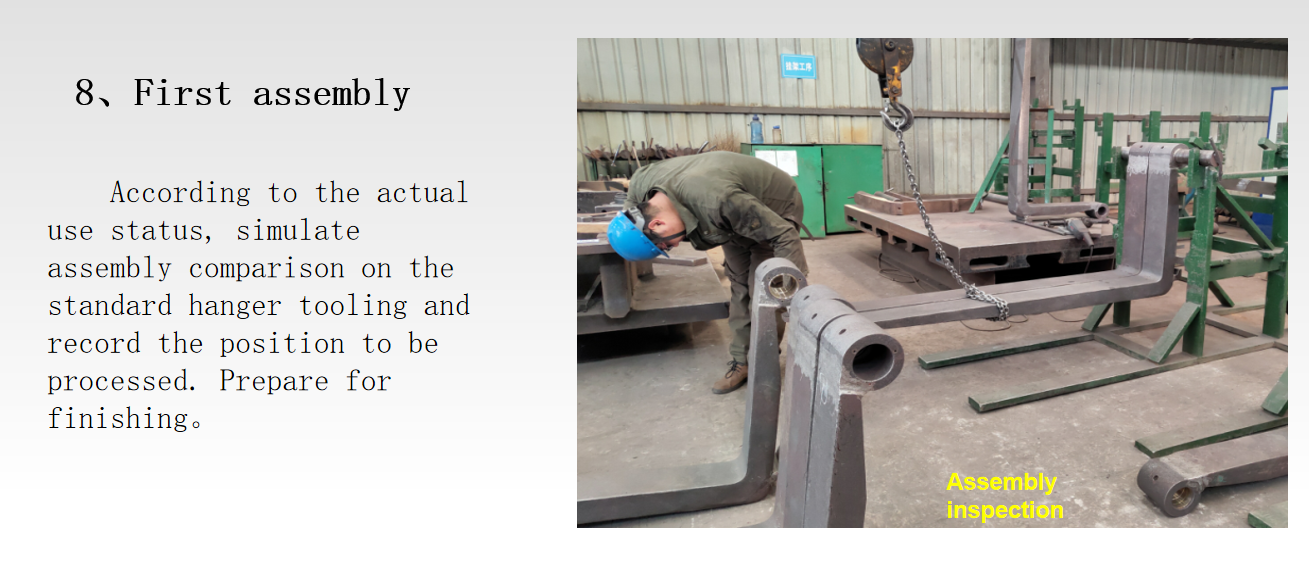

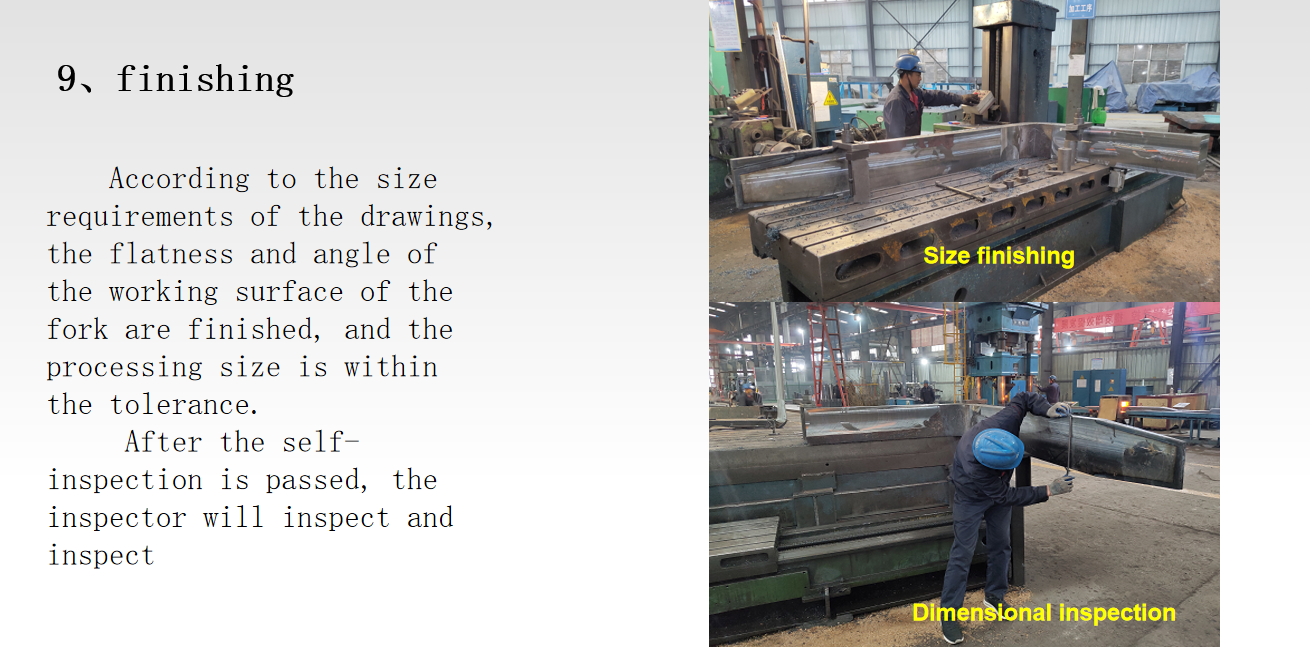

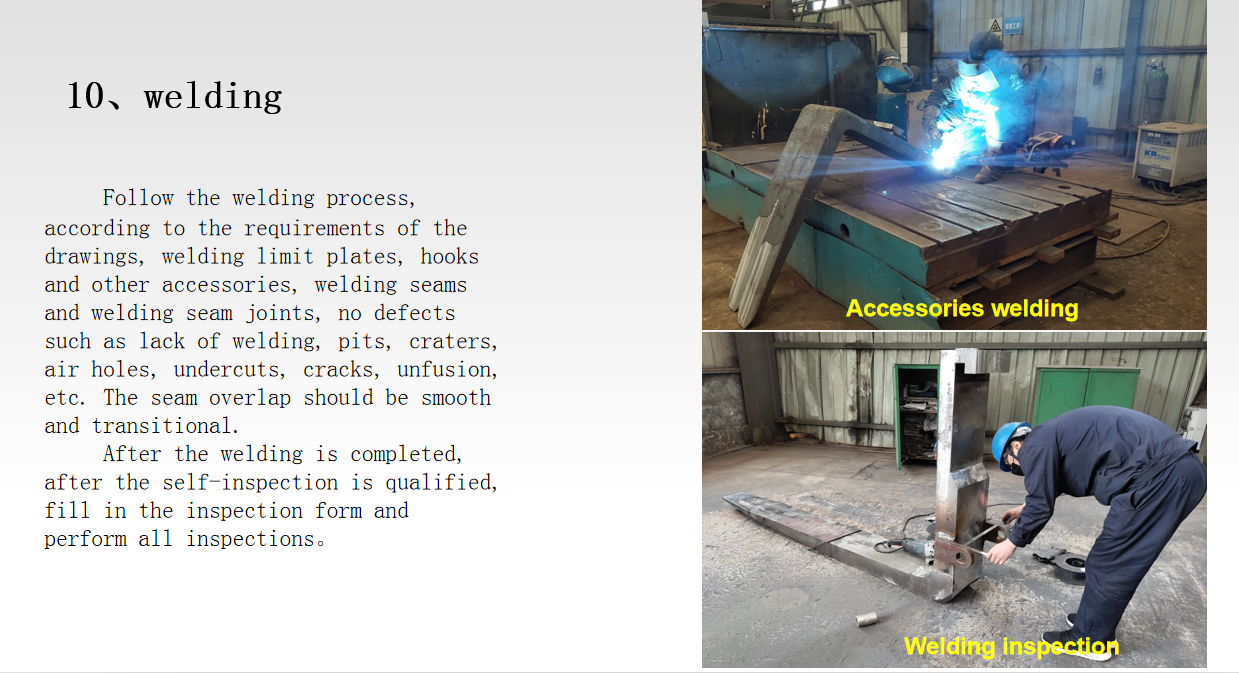

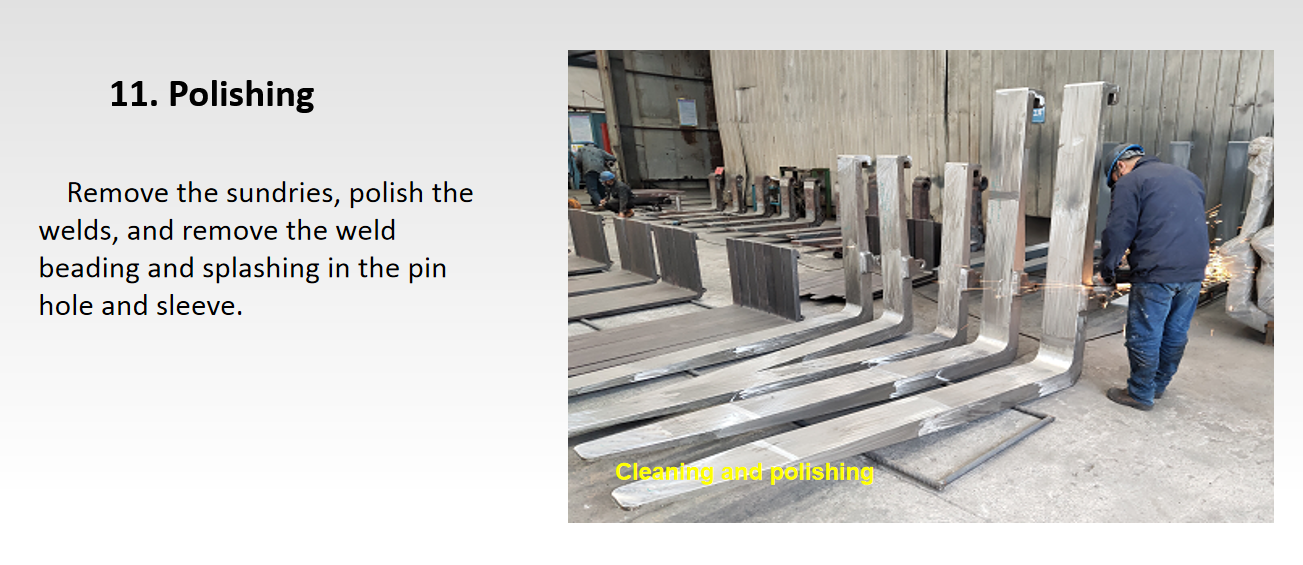

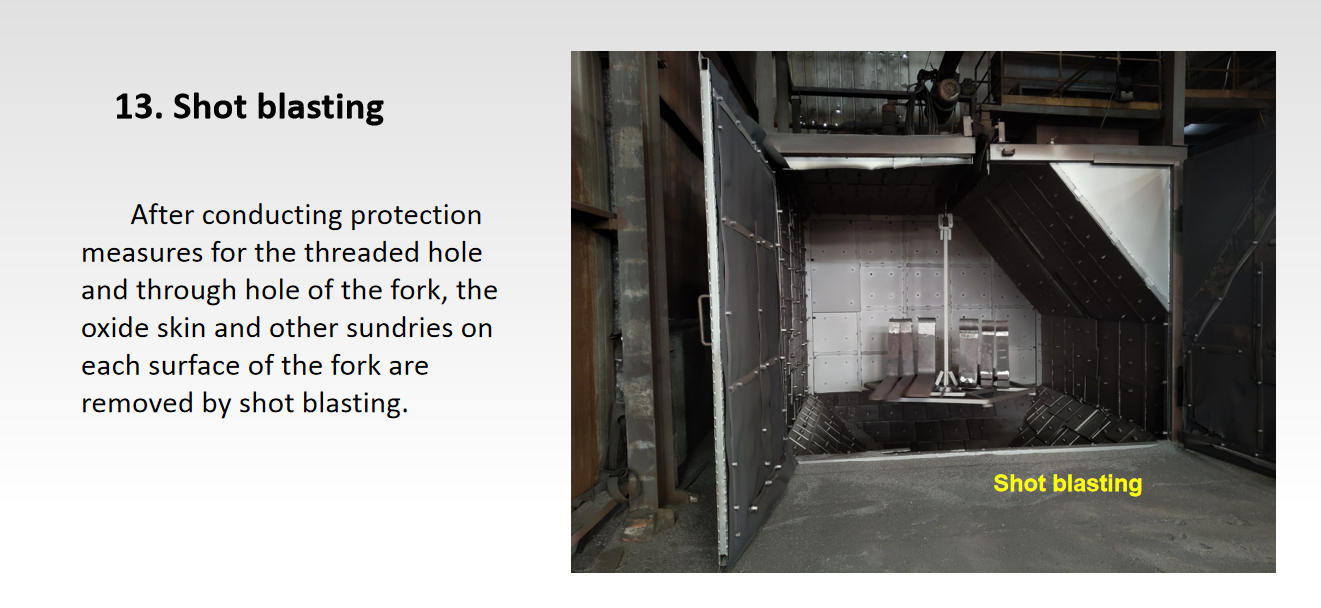

The company regards quality as the basis and regards quality as life. Obtained ISO9001 / 2000 "Quality Management System" certification in 2007, and established a continuous and effective quality control, supervision and assurance management and control system. The production of hook type forks is carried out in accordance with the standards of GB / T5184-2008 / ISO2328: 2007 "Installation Dimensions of Forklift Hook Type Forks and Fork Frames" and GB / T5182-2008 / ISO2330: 2002 "Technical Requirements and Test Methods of Forklift Trucks and Forks" . Guided by the core values of "forging with integrity, sharing for win-win", over the past ten years, it has formed a stable customer base of domestic forklift manufacturers and Europe, the United States, Singapore, Australia, South Korea, etc., and strives to build the fork that is most satisfied by domestic and foreign customers. Brand.